Didn't Find an Answer?

If you don’t see the answer you need, our team is here to help. Click below to contact us and we’ll get you the info you need.

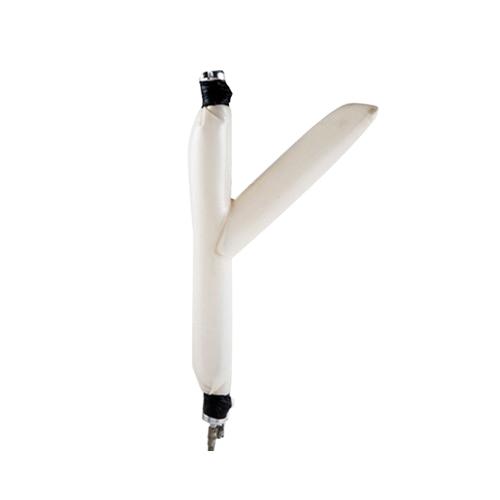

What is inversion lining and how does it work?

Inversion lining is a trenchless pipe repair method where a resin-saturated liner is inverted (turned inside out) using air or water pressure into the host pipe. Once installed, the liner is cured in place, creating a new, seamless pipe inside the old one.

What types of pipes can be repaired using inversion lining?

Inversion lining works on a wide range of damaged pipes, including clay, cast iron, PVC, and concrete. It’s commonly used for sewer laterals, mains, and storm drains from 2" to 24" diameter depending on equipment and liner.

What resins are used in inversion lining?

Epoxy, polyester, and vinyl ester resins can be used, depending on project requirements, chemical resistance, and curing methods. Epoxy is popular for its strength, adhesion, and minimal shrinkage.

Can inversion lining handle bends and transitions?

Yes, inversion lining can navigate multiple bends (typically up to 90°) and diameter changes when using the correct liner type and installation method. Always confirm liner compatibility with your supplier.

How long does it take to cure an inversion liner?

Cure times vary by resin type, pipe size, and curing method (ambient, hot water, or steam). Some projects can cure in as little as 1-3 hours with the right setup.

What equipment do I need for inversion lining?

You’ll need an inversion drum or box, air or water pressure source, resin, liners, calibration tube (if needed), and curing equipment like hot water or steam units. We can help you select the right setup for your projects.

Why is pipe cleaning important before inversion lining?

A clean pipe ensures proper liner adhesion and curing. Debris, roots, grease, or scale can prevent the liner from seating correctly, leading to failures or voids. High-pressure jetting or mechanical cleaning is recommended.

How clean does the pipe need to be before lining?

The pipe should be free of all debris, roots, grease, and loose scale. A clean, stable surface allows the liner to fully invert and bond. Use CCTV inspection to confirm cleanliness and identify defects.

How do I verify the pipe is ready for lining after cleaning?

Perform a final CCTV inspection to confirm the pipe is clean, round, and free of standing water or defects that could impact inversion. Document the condition before proceeding with liner installation.

Can damaged or collapsed pipes be lined using inversion methods?

Severely collapsed or structurally compromised pipes may need point repairs, robotic cutting, or spot patching before inversion. The host pipe must be open and stable enough for the liner to pass through and cure properly.

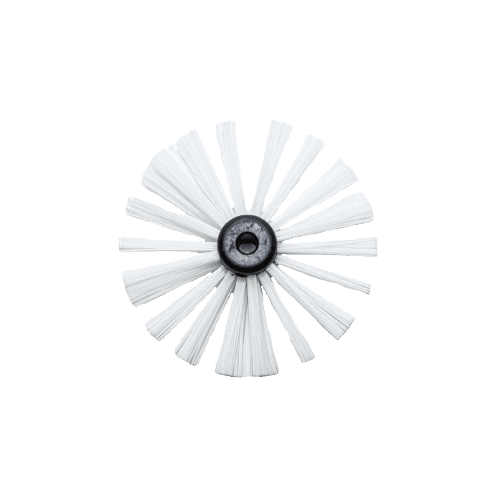

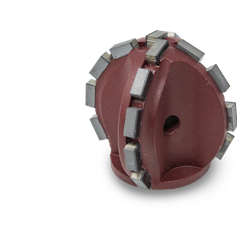

What type of cleaning equipment is best for preparing pipes?

High-pressure water jetting is the standard, but in heavily scaled or deteriorated pipes, mechanical chain cutters or milling robots may be required to restore proper flow and shape before lining.

Should I plug or bypass active flows during preparation and lining?

Yes, controlling flow is critical. Use plugs or bypass systems to ensure a dry, clean pipe during liner installation and curing. Active flows can cause liner deformation or incomplete curing.

Do I need to dry the pipe before coating?

Yes, the pipe must be completely dry. Use blowers or drying equipment to remove moisture. Water or condensation can affect the bond strength and curing process of the epoxy.

How do I know the pipe is ready for epoxy coating?

Visually inspect the surface for cleanliness and dryness. Perform a wipe test to check for remaining residue or moisture. If in doubt, use CCTV to confirm the pipe’s condition.

Do I need to roughen the surface before coating?

For heavily corroded or smooth pipes, mechanical abrasion (like sanding or milling) may be needed to create a profile that helps the epoxy bond better to the host pipe surface.

What happens if the pipe isn’t properly prepared before coating?

Improper preparation can lead to coating failures such as blistering, delamination, or uneven coverage. This can compromise the pipe's integrity and require costly re-coating or repairs.

Can I apply epoxy coating over wet or greasy surfaces?

No, epoxy will not bond to wet, greasy, or contaminated surfaces. The pipe must be completely clean, oil-free, and dry before applying any epoxy coating for a successful bond.

When should I choose epoxy pipe coating instead of pull-in-place or inversion lining?

Epoxy pipe coating is ideal for small-diameter pipes, tight bends, or when maintaining maximum flow capacity is important. It’s minimally invasive, fast, and doesn’t require major access points. Coating is often used for potable water lines, vent stacks, or situations where full structural liners like pull-in-place or inversion may be overkill or impractical. Lining methods are better when the pipe is severely damaged or needs structural reinforcement.

What is Trenchless Supply Inc.'s return policy?

We accept returns on unused, undamaged items within 30 days of purchase. Products must be in original packaging. Custom or special-order items may be subject to restocking fees or be non-returnable. Contact us before returning any items.

What are your shipping policies?

We ship nationwide and offer standard and expedited options. Shipping charges and lead times will be provided at checkout or during quoting. Oversized or freight items may require special handling.

Does Trenchless Supply offer product training?

Yes, we provide in-person and remote training for Spraypoxy systems, CIPP lining, and more. Training can be scheduled at your location or ours. Contact our team to discuss training options and availability.

What payment methods do you accept?

We accept major credit cards, ACH payments, wire transfers, and company checks (with approval). For established customers, net terms may be available upon credit approval.

Does Trenchless Supply offer technical support after purchase?

Yes, we offer ongoing technical support for all equipment and products we sell. Whether you need troubleshooting help, parts, or service advice, our support team is available to assist.

Can I get a quote before placing an order?

Absolutely. We provide formal quotes for all products, services, and training. Quotes are typically valid for 30 days. Contact our sales team for a customized quote based on your project needs.

Need answers fast?

Tap to call our team directly. We’re ready to help with product support, orders, or technical questions.