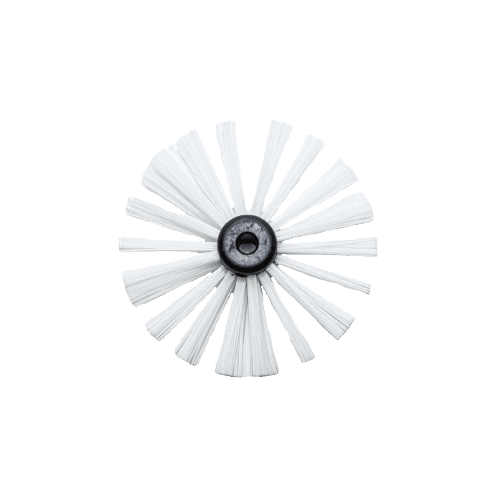

Aggressive Descaling

Eats through hard scale and buildup in old cast iron pipes to restore full diameter and flow.

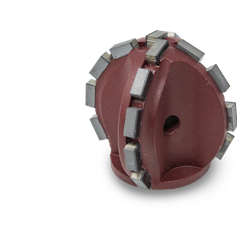

Root & Blockage Removal

Grinds out roots and clears heavy obstructions with powerful, high-torque cutting action.

Reinstatement Grinding

Quickly reopens branch connections after lining, with precision control at the cutter head.

Prep for Lining or Coating

Perfect for surface prep before epoxy coating or CIPP lining — leaves pipe clean and ready.

Built for the Field

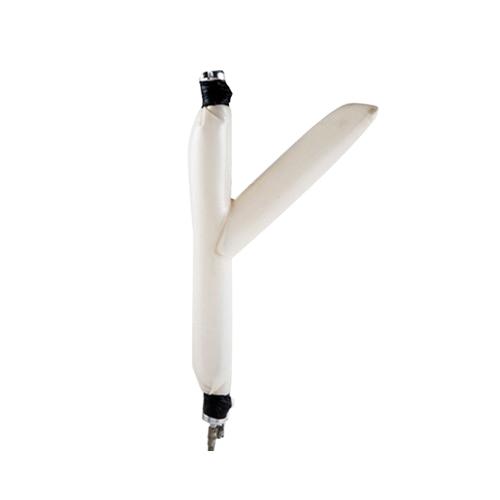

The RotoMidi is built to perform in demanding conditions, with the torque and flexibility needed for aggressive cleaning inside residential and commercial pipes. Whether you're tackling heavy scale, roots, or prepping for a liner, this unit is ready for the job.

✔ Ideal for 2"–8" residential drain, waste, and vent lines

✔ Full Aluminum Frame

✔ Fits through standard cleanouts and access points

✔ RPM 0 - 1500 / min - 110V 15A-20A Power

✔ Shaft Size 3/8" (10mm)

✔ Height 35" - Length 35" - Width 19"

✔ Weight 175lbs

✔ Length 92ft

RotoMidi Aids Pipe Lining Prep

RotoMidi Aids Pipe Lining Prep

Stuart Plott, an apprentice at Zippity Split Plumbing in Phoenix, poses with the company’s Boldan RotoMidi milling machine, made by Finland-based Boldan Oy. The company primarily uses the machine to more efficiently prep cast iron drainlines for pipe lining, as well as reinstate branch lines. - Cleaner Magazine

When Mark Carrasco decided to name his business Zippity Split Plumbing, he knew he was setting the bar high for fast and responsive service.

As a result, when Carrasco invests in equipment speed, efficiency and productivity are top of mind. A good example is the RotoMidi, a pipe-milling machine.. that Carrasco bought from Trenchless Supply in late 2022. The machine cost about $10,000, but he says it has more than paid for itself through increased efficiency.

“It allows us to do more jobs per year than we otherwise might do,” says Carrasco, who established Zippity Split Plumbing in Phoenix in 2019. The company employs 12 people, runs nine service vehicles and primarily focuses on trenchless pipe lining throughout the metro Phoenix area.

“You literally could pay for this machine with just 10 descaling jobs,” he adds, noting he uses the RotoMidi primarily for prepping 3- to 4-inch-diameter cast iron pipes for lining. “Or it could pay for itself with one commercial lining job with 300 to 400 feet of pipe. Quite honestly, if you’re in the trenchless pipe rehab space, $10,000 is not a big investment. But you can’t put a price on productivity.”

Compared to other units he’s used, Carrasco says the machine’s compact size and features provide a built-in advantage in terms of maneuverability in tight places, which boosts productivity. Take the wheels, for example. Two of them are swiveling caster wheels, which makes it easy to maneuver in a small hallway or bathroom.

“It sounds silly because it’s such a small thing,” Carrasco says. “But it makes it 10 times easier to swing it 180 degrees in, say, a hallway. It makes the machine much easier to use.”

In fact, the caster wheels are only one of several small details that yield big productivity results, Carrasco says. There’s the foot pedal that allows an operator to keep both hands on the cable. Furthermore, the pedal is removable and the wires that connect it to the machine can be stored in a compartment.

“One of the biggest problems I’ve had with other machines is that you can’t remove the cord, so the wire always gets kinked to the point that you eventually have to cut it and resplice it,” Carrasco says. “And that always seems to happen on a job site, which causes downtime.”